Meter-Mix Dispensing Basics

By Jon Urquhart, Director of Applications Engineering

What is Meter-Mix?

In the world of bonding, filling, and encapsulating the term “meter-mix” refers to the process and the hardware required to accurately manage, blend, and dispense multi-part fluids in an automated fashion. Most often in electronics and industrial dispensing, meter-mix dispensing is based upon processing a 2-part adhesive that is supplied as a base component plus a hardener component which when mixed in the proper volume and ratio cause a chemical chain reaction that initiates the curing process of the mixture. The reaction time can be as little as a few minutes up to hours or even days before achieving its final cured state. Once a 2-part adhesive is mixed, the end user should be aware of the specified “pot life” as this is the duration of time where the mixture can be used before the viscosity (or thickness of the liquid) increases beyond its useable state. In automated dispensing, once a mixture changes viscosity by even as little as 5-10%, this can have a negative effect on the consistency and repeatability of the process. Careful planning needs to take place to properly specify the correct metering and dispensing equipment.

Meter-Mix Applications

A 2-component adhesive formulation may be chosen over a 1 part adhesive due to performance benefits such as short cure times, enhanced durability, or improved adhesion. One of the most widely used applications of meter mix equipment is in the potting process where an enclosure with a circuit board is filled to a certain level to protect the electronics from moisture, dust, foreign objects, etc… A potting process can be applied to protect small electronic sensors used in the medical or automotive industry, or used to fill larger devices such as motor controller housings, LED video board assemblies, or electric batteries. A potting process can be a simple benchtop configuration where an operator may position a housing underneath a nozzle then step on a foot pedal to initiate the dispense into a single location for given amount of time or preset volume. In this case the viscosity of the potting material is low enough to freely flow into all required areas.

More intricate 2-component dispensing applications may require a multi-axis robot to drive a nozzle along a preprogrammed path to apply very small beads or deposits of adhesive to bond a mobile electronics assembly, or apply varying amounts of thermal gap filler materials with high accuracy to an automotive engine control module. Other precision applications may include staking of components to a circuit board or dispensing an encapsulant over exposed wire bonds. In these applications, the automation must be taken into consideration in order to apply medium to high viscosity adhesives at the proper flow rate and pattern in order to implement a successful process in production.

▲ LED ▲ Telecommunications

▲ Industrial ▲ Automotive

▲ Military ▲ Consumer Electronics

▲ Aerospace ▲ Medical Devices

The Basics

A fluid delivery system used for meter-mix dispensing consists of 4 main components:

Reservoirs can range in size from as little as a syringe when dispensing milliliter size shots up to drums to supply systems dispensing liter sized volumes. Metering pump technologies vary and must be chosen according to desired flow rate and type of medium to dispense. The dispense valve and mixing device are typically combined into a single unit but each play their own role in providing the proper dispense control and blending of each fluid component.

Metering Pumps

Many types of pumps are available for accurately moving fluids but there is no true “one size fits all” technology that meets every capability requirement for all dispensing processes. There are many factors that come into play when outlining a meter-mix system such as: desired flow rate, cure rate of the mixed composition, filler content and type (if any), viscosity, mix ratio, and process budget. For this article we will be discussing the 3 most common pump types used by PVA:

Gear

Fluid is fed into a chamber containing 2 gears that rotate inside a machined cavity. The gear teeth drive the fluid along the circumference of the chamber then force it to the pump outlet. One

gear shaft is connected to a servo motor which provides precision control of the dispense rate. Pump accuracy depends on the machining tolerances between the gear teeth and pump walls. Gear pumps are available in various sizes and are typically rated on volume dispensed per revolution. An example fluid used with a gear pump system may be an unfilled silicone adhesive.

Rod/Piston

Rod displacement pumps consist of a cylinder with a single port on one end and a rod that can extend or retract within the chamber. The fluid port acts as the inlet or outlet depending on the state of operation. When the rod is retracted, a nearby outlet valve is closed while an inlet valve is opened to allow pressurized fluid to feed into the cylinder. When ready to dispense, the inlet valve is closed and the outlet valve is opened. Then the rod extends to displace the fluid inside the chamber and feeds at the desired amount and flow rate. High precision units are configured with a linear servo drive to allow for a programmable feed rate. These are used for filling and gasketing applications. Basic units may offer a pneumatic drive to provide simple shot/filling capability but are not always suitable for precision line dispensing. An example fluid used with a rod displacement system may be a high viscosity and highly abrasive thermal interface gap filler.

Progressive Cavity

Progressive cavity pumps use a rotor-stator combination where a helical rotor spins inside of a molded seal which contains a number of cavities. As the rotor spins, the fluid inside of each cavity gets pushed toward the outlet of the assembly. Due to the servo control on the motor and the tightly sealed assembly, the rate of rotation will directly impact the pump’s output rate with a very linear relationship. For example, if the rotor RPM doubles, the flow rate will double as well.

By design, each cavity inside the stator will flex as the rotor spins to allow the fluid to advance forward with each rotation then re-seal. Constant rotation of the pump provides for continuous dispensing with no limitation on shot size. The flexible seal design allows for the use of fluids with some fillers without imposing high levels of shear which could change the fluid properties or grind up large filler particles. The progressive pump design allows for processing of low to medium/high viscosity fluids, without concern of dripping or leaking. An example fluid for a progressive cavity system may be an acrylic or urethane adhesive with glass spacer beads throughout.

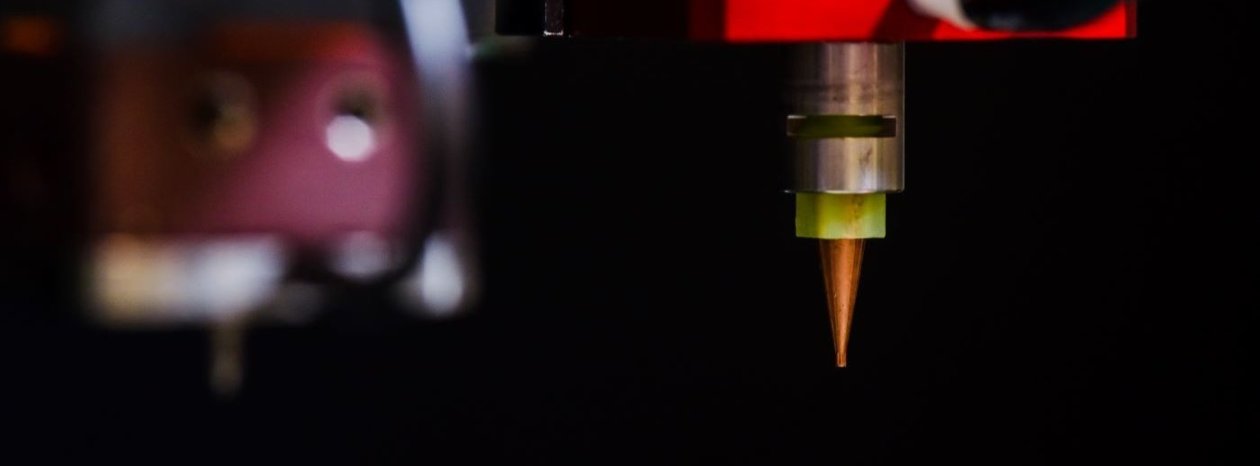

Mixing & Dispensing

Once the fluids are delivered at the proper ratio and rate, the 2 components must be mixed to initiate the cure process. Two component adhesives are typically mixed just prior to the application point using a valve with on/off control coupled with a disposable mixing element. There are a range of valves available with varying flow rates but generally speaking there are 2 methods of mixing: static or dynamic mix.

A static mixing valve utilizes a static mix tube attached to the outlet of the fluid body to channel the 2 fluid components along a number of helical or stepped elements molded together in an alternating pattern and fixed inside of a plastic tube. The elements are aligned in such a way that creates a flow path which forces the 2 components together to continuously mix as the fluid travels through the tube.

A wide variety of static mixers are available. The correct mixer is chosen based on the flow rate of the system, viscosity of the fluid, and pot life of the mixture. Choosing a mixer with too few elements will result in improperly mixed material and poor curing and/or adhesion, while choosing a mixer that has too many elements may cause pre-mature curing of the adhesive inside the mixer which leads to inconsistent dispensing. Static mixing works well for fluids with A and B components that are relatively close in viscosity or requires nominal mix ratios such as 1:1 up to even 10:1 in some cases.

Some examples might be silicone or epoxy-based resins. A dynamic mixing valve utilizes a disposable paddle or similar static type mixer that can spin within the flow path to blend the 2 components as they travel through the mixing chamber. The number and type of dynamic mixing elements may be limited but the mixing valve will have a setting that allows for choosing the

rotation speed of the mixer to achieve the correct mix. Too slow of a mixer speed can result in improperly mixed material and poor curing and/or adhesion. Too fast of a speed can lead to premature curing inside the mixing chamber which leads to inconsistent dispensing.

Dynamic mixing systems provide higher levels of shear on fluids than static systems. This allows for processing of fluids with A and B components that may have a wide viscosity delta and/or a wide mix ratio, such as a urethane based adhesive, in some cases up to 100:1.

Considerations for Defining Meter-Mix Equipment

There are many instances where an engineered meter mix system is the right choice as a dispense solution. While the vast array of possibilities may seem difficult to define, getting answers to the four main areas below will help start the process of creating a solution in a reasonable time frame.

- Define part A and B materials. The material manufacturer may need to provide information on the following:

- Viscosity in centipoise

- Specific Gravity (or density)

- Base chemistry (silicone, urethane, epoxy, etc.)

- Identify any filler materials

- Identify any special properties such as shear thinning or thickening

- Provide the Technical data sheet and MSDS

- Define the mixing ratio and target accuracy of the chemistry. For example:

- A specification of 10:1 +/- 10% translates to an acceptable variation on the mix ratio from 9:1 to 11:1. Is this an acceptable range for the process or is something more like 2-3% required?

- Define the production rate. This is typically expressed through the items below:

- Shot size with accuracy

- Accuracy Example (10gram shot +/- 10%)

- Flow rate with accuracy

- Accuracy Example (100grams/minute +/- 10%)

- Define the supply system. The previous 3 areas will lead to a target amount of fluid to use within the system. The below questions will help determine the final configuration:

- What are the available material container sizes?

- Which size is intended for production?

- Does this size make sense with the usage rate in production?

- If there are fillers that can settle out of the fluid, do they require agitation or recirculation? If yes, the supply tank and flow path may need special options.

Conclusion

While the many variables involved may seem overwhelming, by understanding the basics of the metering technologies available along with the fluid properties, an appropriate meter mix system can be developed quite easily. More information provided at the beginning of a project will minimize the chance of any processing issues during implementation of equipment. Well-defined metering and fluid handling can lead to a stable dispensing application in production.