What is Dam and Fill?

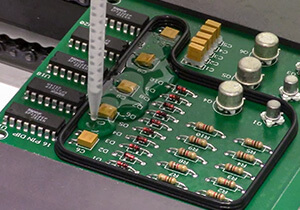

Dam and Fill is a two-step process of first dispensing a high viscosity fluid around the perimeter of a device or electronic circuitry, and then dispensing a low viscosity fluid within the perimeter to fully encase the components. The dam can be applied as a single or multi-layer bead depending on the target fill height required.

When to Use Dam and Fill

A dam and fill process is ideal for encapsulating an area of components or a wire bonded die. This process can precisely control the wetted area of a PCB during this stage of assembly.

Using a silicone material during the process adds higher shock and thermal resistance than a conformal coating process.

Benefits of Dam and Fill

- High shock and vibration resistance

- Water and moisture resistance

- Controlled filling compound

- Materials vary widely

- Use in small and large areas

- Stronger than conformal coating

Questions about your dam and fill process?

Talk to the PVA ExpertsRecommended Dam and Fill Valves

PVA offers a wide variety of valves ideal for any dam and fill application.

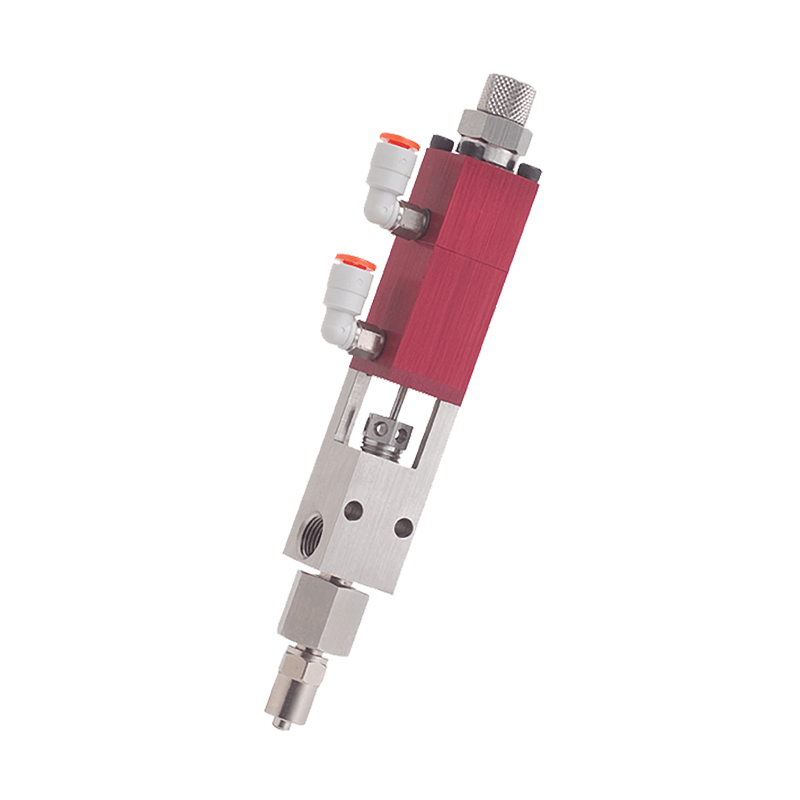

FC100 Series

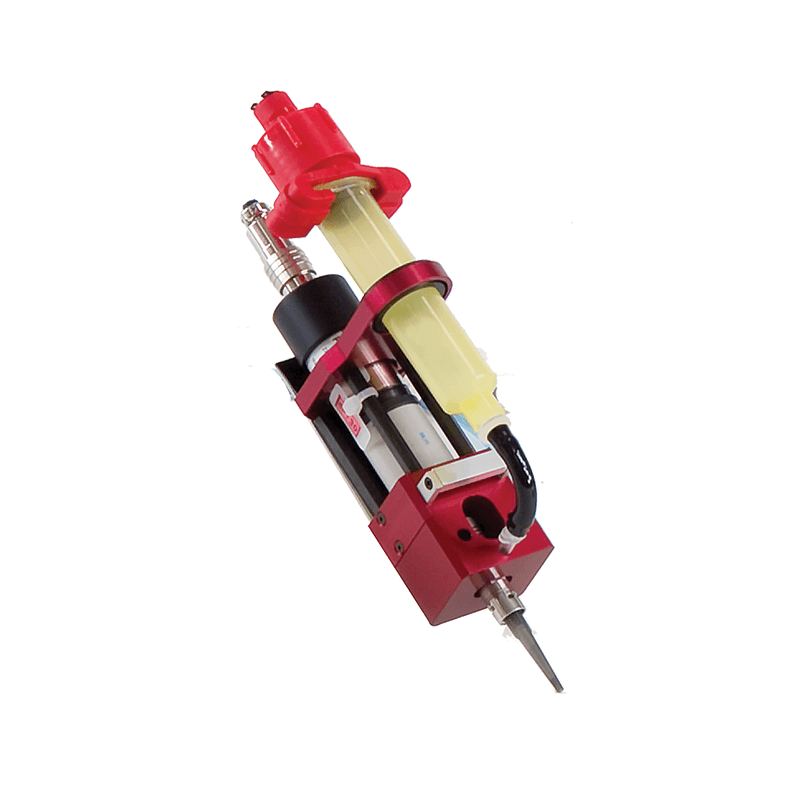

PCP

SV200

Dam & Fill Videos

FC100-MC for Optimized Dam and Fill Applications