What is Encapsulation?

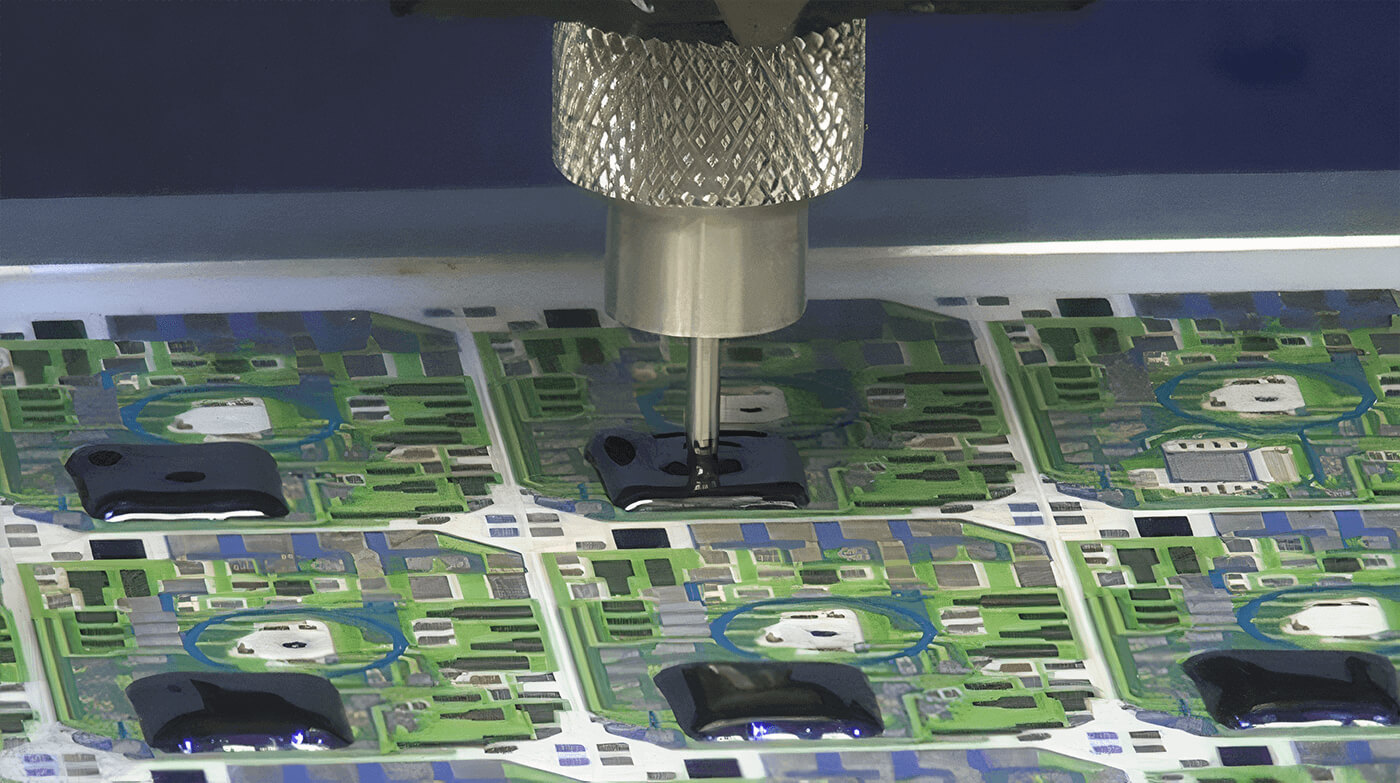

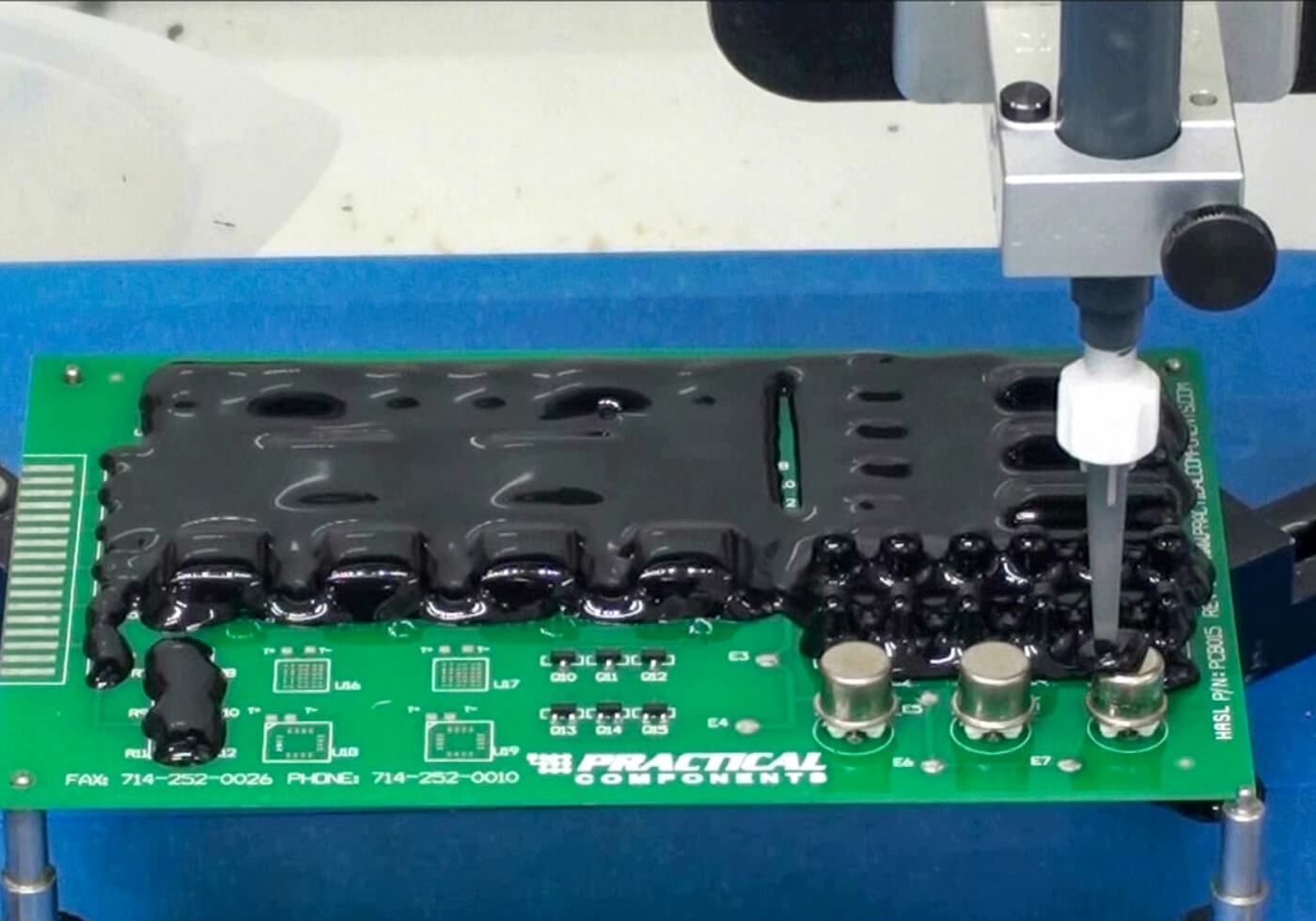

Encapsulation involves covering an electronic assembly or component with a compound to protect the device from mechanical stress, moisture, corrosion, and foreign debris.

When to Use Encapsulation

Encapsulation is used to apply an epoxy or silicone-based fluid that completely covers a defined area around a flip chip or wire bonded component. The encapsulation process provides components with shock and heat resistance for harsh environments leading to longer product reliability. Encapsulation can be very similar to potting, however is utilized to protect a device without the presence of a case or frame.

Benefits of Encapsulation

- Increased component longevity

- Heat and shock resistance

- Moisture and corrosion resistance

- Withstand harsh environments

- Thick and more robust solution

- Use without the need for a case or frame

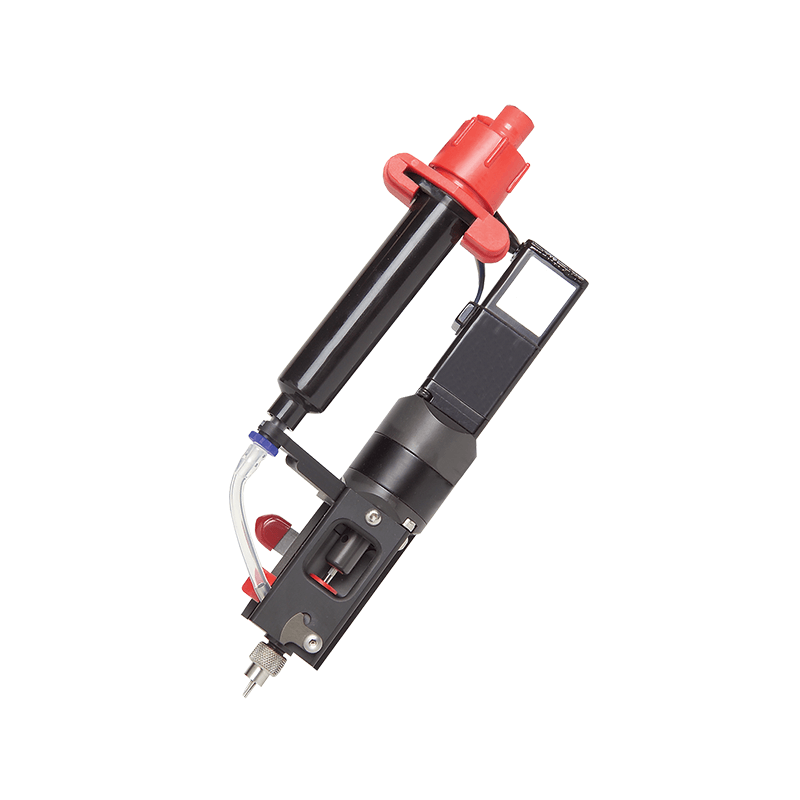

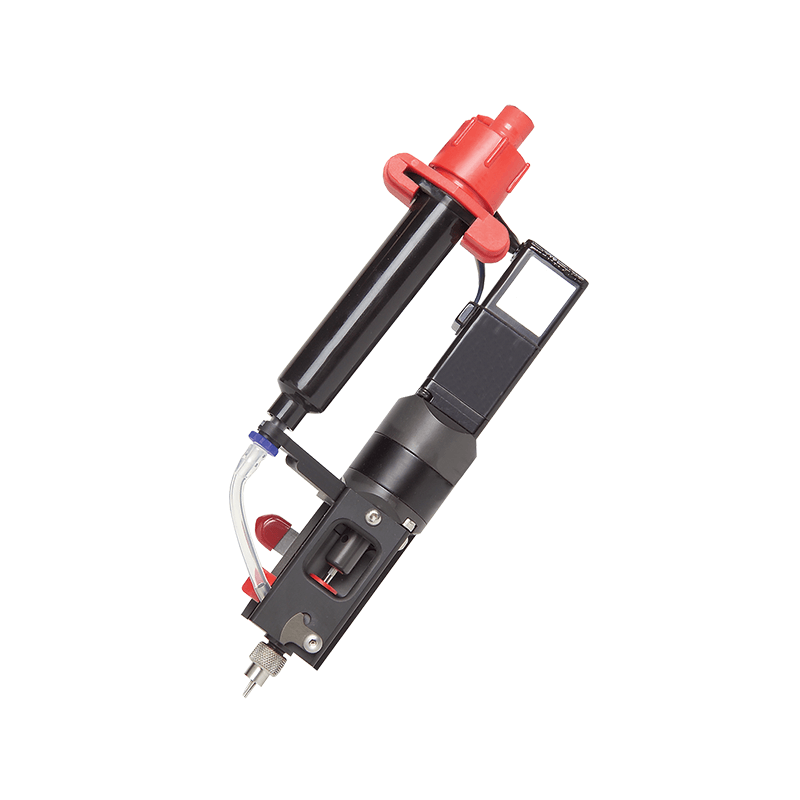

Recommended Encapsulation Valves

PVA offers a wide variety of valves ideal for your encapsulation process.

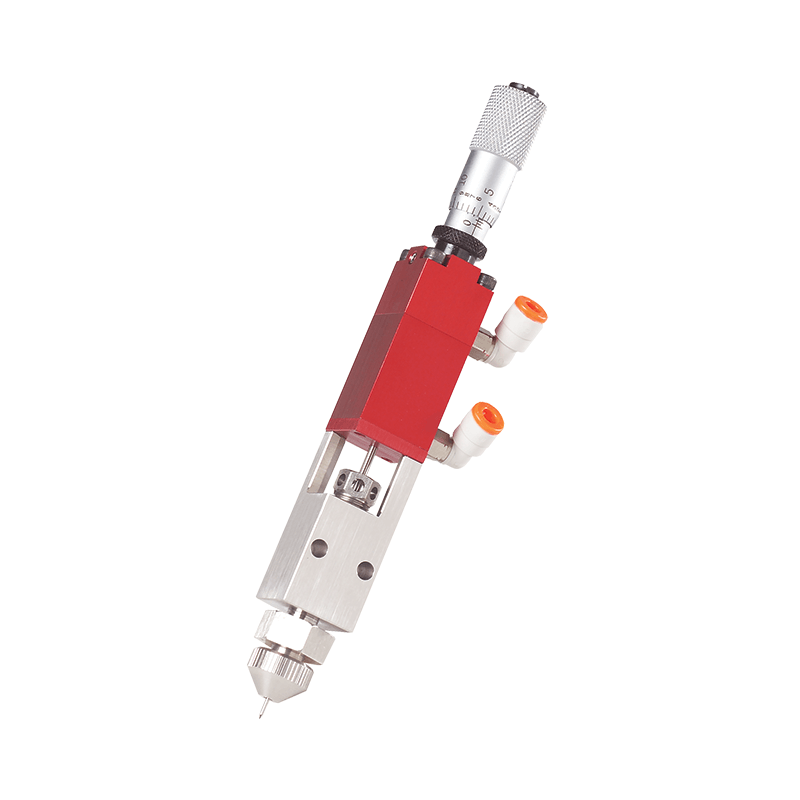

FCM100

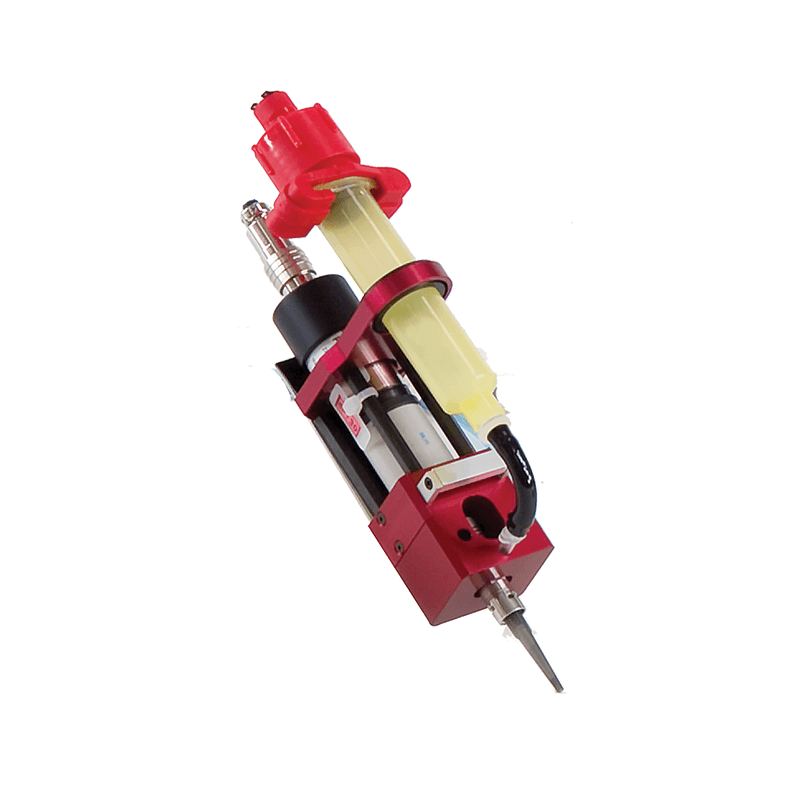

SV200

Questions about encapsulation?

Talk to the PVA ExpertsEncapsulation Videos

Application Spotlight: Encapsulation