What is a Thermal Interface Material?

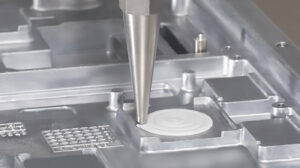

A thermal interface material (“TIM”) fills gaps between mating surfaces with a substance that improves thermal conductivity beyond the air that would have otherwise filled that gap.

When to Use TIM

Thermal Interface Materials (TIM) are used to improve distribution of heat between integrated components and heat dissipating devices. TIM materials fill nano-sized imperfections caused by machining processes. These nano-sized gaps can decrease the thermal conductivity between two surfaces when only air is present. TIM materials come in a wide variety of chemistries depending on the needs of a component. Thermal grease and semi-adhesive TIM materials improve the reliability of integrated components and heat sinks.

Benefits of TIM

Thermal Interface Materials (TIM) offer a multitude of benefits for electronic devices and components. By utilizing TIM, components experience increased longevity, as the material enhances heat sink effectiveness and heat displacement, thereby ensuring optimal operating temperatures. This not only improves component reliability but also extends their lifespan. Moreover, TIM provides versatility with its wide range of viscosities, accommodating various thermal management needs. Additionally, TIM efficiently fills large component gaps, ensuring seamless thermal conductivity throughout the system, ultimately enhancing overall performance and reliability.

Applications

Thermal Interface Materials

A thermal interface material (“TIM”) fills gaps between mating surfaces with a substance that improves thermal conductivity beyond the air that would have otherwise filled that gap. The TIM acts as a conductive bridge that greatly improves heat transfer between between a heat-generating device (e.g. an integrated circuit) and a heat-dissipating device (e.g. a heat sink).

Contact

Halfmoon, NY 12065